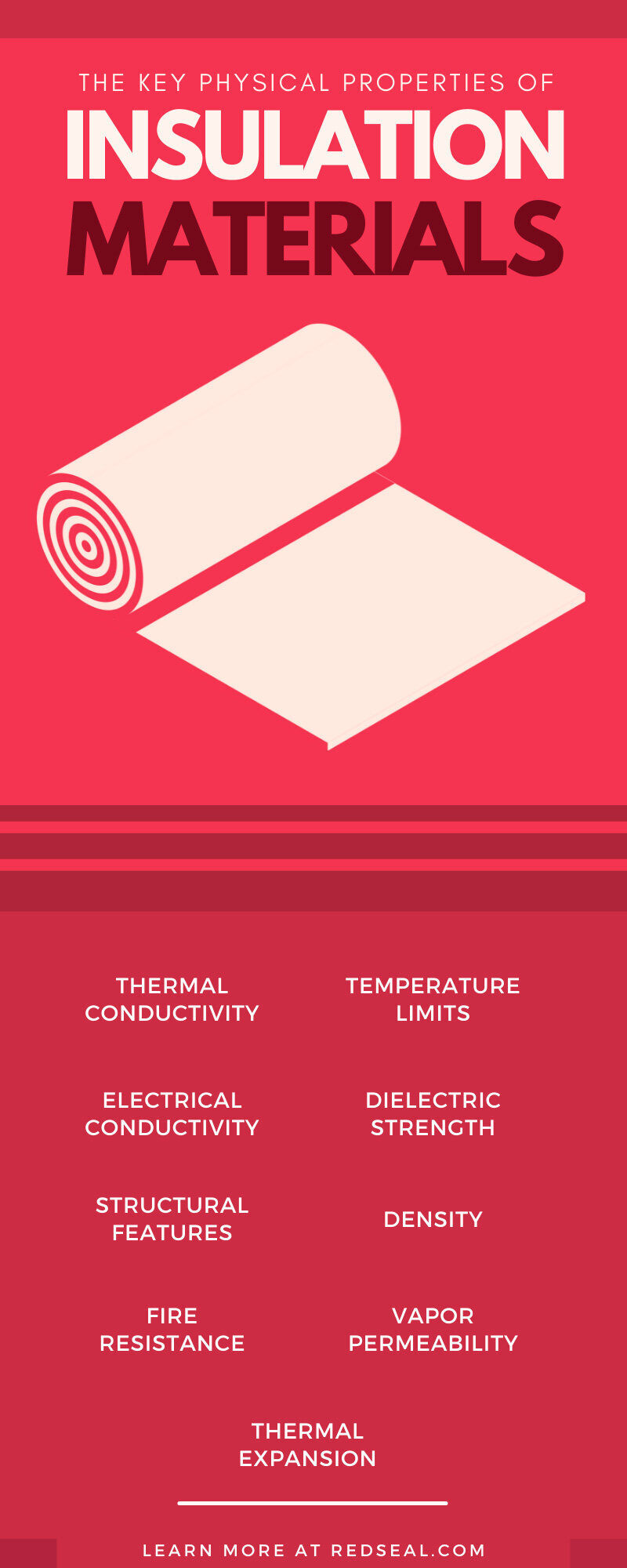

Properties of Insulators

Everything from industrial furnaces to smartphones needs protection to keep people safe. However, working with unpredictable elements and hazardous materials creates a dangerous environment where people could sustain serious harm. That is where insulation comes in. Here are the key physical properties of insulation materials.

Insulation Capabilities

The first thing you will want to understand about the properties of insulators is how exactly they insulate. Whether you need protection from heat or electricity, you must know a material’s ability to prevent the flow of these elements.

Thermal Conductivity

Thermal conductivity, as the name suggests, measures how well an item allows heat to pass through it. When two objects touch, heat transfers between them, even if it a nominal amount. Think about a time when you have touched an ice cube. The first thing you felt was the stinging cold of the ice against your skin—the ice transferring its low temperature to you on contact. Yet, if you keep holding the ice, your body heat will transfer to it and melt the cube into water.

Thermal conductivity works the same way in all scenarios—heat moves between solid, liquid, and gas objects in contact. The only difference is how fast. Some thermal insulators have relatively high thermal conductivity and cannot keep the heat at bay for long. Other physical properties of insulating materials can allow them to resist thermal transmittance for a long time, keeping heat trapped in the desired area.

Temperature Limits

By definition, a thermal insulator must interact with high temperatures. Yet, every item has a melting point, though it may be incredibly high. When evaluating the properties of insulators, you must consider the operating temperature limits for a material. If foamed plastic continues to melt at your current operating heat, it might be time for higher-quality items that can withstand your production needs.

Electrical Conductivity

Insulation applies to more than heat management; electricity must stay in its place, too. Electrical conductivity describes the ability for electricity to pass through an object. High electrical conductivity means the object allows electricity to move through it. Items like copper wires and superconductors must allow electricity to flow.

However, electrical conductivity should be quite low for electrical insulation materials. These insulators must keep electrical flow within set boundaries; otherwise, loose electricity could flow freely. Electrical insulation reduces the likelihood of electrocution and electrical fires, improving the safety of all people and machines nearby.

Dielectric Strength

Electrical insulation can resist strong currents of flowing electricity. However, insulators have a breakdown point where their electrons bend to the will of the current and become conductive. An insulator’s dielectric strength describes this phenomenon and how much voltage a material can take.

Dielectric strength is crucial to measure for each material since it will directly impact the application. If you need an insulator to withstand ten kilovolts per millimeter, you cannot use a material that will become conductive at eight. Thus, dielectric strength is a great way to compare materials and find the right fit for your industrial usage.

Structural Features

While every insulator relates to the thing it insulates from, there are other properties that determine its viability for use. These more structural features are critical to assess before implementing a material.

Density

The density of a material determines the speed of movement for electricity or heat through it. Imagine a heat source trying to warm your hand on the other side of a piece of paper. The heat would pass through that thin, low-density object quite quickly, and you would feel the heat almost immediately. But replace the paper with a high-density piece of polished concrete, and it would take quite some time for you to feel anything. That is because the amount of matter per unit of volume in an item is a determining factor in the rate of diffusion.

Fire Resistance

In situations involving heat or electricity, a fire could start at any moment. Molecules that heat up only need the slightest jolt to create a full-on flame. Fire resistance is a crucial reading for engineers to anticipate. A material’s fire resistance classification determines the scope of applications available.

The ignitability of a material is a serious concern to worker safety in an industrial facility. Therefore, one of the most important properties of insulators is fire resistance, as this helps protect your workforce. Materials with a low softening point can either melt or catch aflame if exposed to extremely high temperatures. If a slightly flammable material insulates against intense heat, it could lead to a fire which endangers the lives of onsite staff.

Vapor Permeability

Many heat processes involve water. At least, the vaporization of water in raw material. When solid items heat, any internal gases and liquids also heat up. It is not unusual for water vapor to rise out of raw materials during product machining. In order to account for this, insulators must have a certain vapor permeability.

A thermal insulator will still retain the heat within its bounds, but the vapors swirling around inside are another story. If the properties of insulators include material with high vapor permeability, it will allow any trapped water through its pores to escape the internal chamber. This is perfect for processes that require a completely dry final product. An impermeable insulator will not allow anything through—heat or liquid. Engineers must account for this phenomenon while working to avoid unwanted water buildup.

Thermal Expansion

Suppose you install a thermal insulating sheet in a tight space to keep heat in an enclosed area. While you’ll need a tightly sealed area that traps the heat, you also need room for items to expand when heated. It is critical to note that a thermal insulator’s thermal resistance will impact how hot the material actually gets, impacting its expansion size.

But in certain settings, an insulator that expands too much in the presence of heat could compromise a system or device. Thermal expansion statistics are vital to the successful implementation of new insulation material.

Remember the key physical properties of insulation materials as you find the next solution for your machining and production needs. If you have any questions about insulation materials, reach out to our team at the Red Seal Electric Company today.